It is well-known for readers who are familiar with the optical or cooling fields that, only 30% of the electric power is transformed into light when a LED light is powered on. The rest of the energy is transformed into heat. Due to this, the critical technique of the design of a LED light structure is to transfer such amount of heat outward as soon as possible. Heat can only be transferred by conduction, convection, or radiation. The temperature within a LED light fixture can only be effectively reduced by transferring the heat outward as soon as possible. This way the LED light is operating at an adequate temperature range and its service life is not affected due to long-term operations under high temperature.

What are the heat transfer paths for LED light fixtures?

The LED light source doesn't emit infrared or ultraviolet rays itself. Therefore, the LED light source doesn't emit heat by radiation. The only heat transfer path for LED light fixtures is through the LED heat sinkwhich is directly attached to the LED base board. Since a LED light heat sink is required to have thermal conduction, convection, and radiation effects, the design and materials used are critical to the performance.

The LED heat sink can conduct heat rapidly from the heat source to the surface of the heat sink and the heat is emitted to the air by conduction and radiation. Thermal conduction only acts as the heat transfer path and thermal convection is a heat sink's main function. Its cooling performance is mainly determined by the cooling area, share, and the capacity of natural convection while thermal radiation is just a supplement effect. Generally speaking, if the distance between the heat source and the heat sink surface is less than 5mm, heat can be transferred outward as long as the material's thermal conductivity is larger than 5 W/m-K. The remaining amount of heat is mainly taken care by thermal convection.

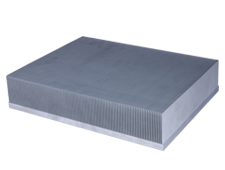

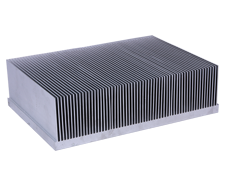

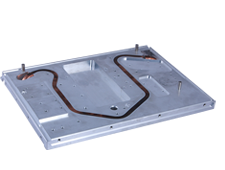

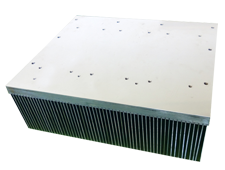

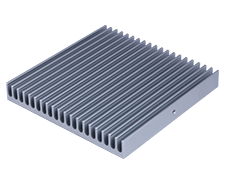

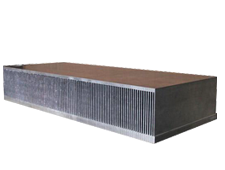

According to the editors' understanding, most of the LED light sources still use low voltage (VG=3.2V), high current (IF=200-700mA) light bulbs. Due to the large amount of heat during operation, it is required to use heat sinks that are made of aluminum alloys of higher thermal conductivity. Therefore, die-casted aluminum heat sinks, extruded aluminum heat sinks, and stamped aluminum heat sinks are commonly used.High-pressure die-casting technique is used to make die-casted aluminum heat sinks. During the process, liquid zinc-copper-aluminum alloy is poured into the feeding port and will be casted by the die-casting machine into the shape of the heat sink based on the design.

In the next article, we are going to discuss the performance and difference between various types of LED light coolers and please stay tuned.